Kawabata Evaluation System

The Kawabata Evaluation System (KES) is a series of instruments used to measure those textile material properties that enable predictions of the aesthetic qualities perceived by human touch. KES instruments quantify garment material tactile qualities through objective measurement of the mechanical properties related to comfort perception.

With low forces applied, as in manipulating / touching fabrics, the Kawabata instruments define the role played by tensile (stretch), shear stiffness (drape), bending rigidity (flexing), compression (thickness, softness), and surface friction and roughness (next to skin) on tactile sensations.

This analytical power, combined with the capability to characterize energy loss in mechanical deformation and recovery processes, provides an unparalleled tool for use in fabric hand analysis. KES provides a unique capability, not only to predict human response, but also to provide an understanding of how the variables of fiber, yarn, fabric construction and finish contribute to perceptions of comfort.

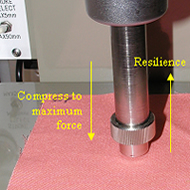

Compression

Compressional properties of a 2 cm2 area are measured with the KES-FB3 Compression Tester at an appropriate force for material type being tested.

- EMC – compressibility, percent comparison of initial thickness measurement to that at maximum applied force. A higher value indicates greater compressibility.

- RC – compressional resilience, percent recovery or regain in thickness, when the force is removed. Higher value indicates a greater recovery from being compressed.

- Thickness – millimeters; measured at 0.5 gf / cm2.

Bending

KES-FB2 Bending Tester measures the force required to bend the test fabric approximately 150°.

- B – bending rigidity per unit fabric width, gf.cm2 / cm. Higher B value indicates greater stiffness / resistance to bending motions.

Surface

The surface properties of friction (resistance / drag) and surface contour (roughness) are determined using the KES-FB4 Surface Tester.

- MIU – coefficient of friction, 0 to 1 with higher value corresponding to greater friction or resistance and drag.

- SMD – geometric roughness, micron; higher values corresponds to geometrically rougher surface.

Shearing

In shear testing, the KES-FB1 Tensile-Shear Tester applies opposing, parallel forces to the fabric, until a maximum offset angle of is reached. A pretension load is applied to the specimen.

- G – shear stiffness, gf/cm.degree, is the ease with which yarns move, resulting in soft / pliable to stiff / rigid structures.Lower values indicate less resistance to the shearing motion; corresponds with better drape.

Tensile

KES-FB1 Tensile Test, measures the stress / strain parameters at a maximum load for the type of material being tested.

- EMT – extensibility or stretch, percent strain at maximum applied force: completely elastic (100%) to inelastic (0%); higher value indicates greater stretch.

- RT – tensile resilience, percent recovery from stretch when the applied force is removed. Higher values indicate greater recovery from having been stretched.