Big Reveal for Nonwovens

This week, NC State welcomes movers and shakers from a global, multibillion-dollar industry as part of the grand opening for a new nonwovens facility on campus.

“Nonwovens may be the best hidden industry we have,” says Behnam Pourdeyhimi, executive director of the Nonwovens Institute. “We’ve been using advanced manufacturing and automation for 60-plus years.”

However, an understanding of the finer points of SpunMelt and hydroentangling technologies isn’t necessary to appreciate the power of nonwovens.

Tom Daugherty, deputy director of the Nonwovens Institute, points out that engineered fabrics are not only an economic force but also a part of our daily lives through consumer products, medical and hygiene supplies, soil-stabilizing geosynthetics, automotive components, filtration systems, wipes and many other products. Daugherty is a new addition to NC State after many years at Procter & Gamble.

Tom Daugherty, deputy director of the Nonwovens Institute, points out that engineered fabrics are not only an economic force but also a part of our daily lives through consumer products, medical and hygiene supplies, soil-stabilizing geosynthetics, automotive components, filtration systems, wipes and many other products. Daugherty is a new addition to NC State after many years at Procter & Gamble.

You may not know it, but you come into contact with nonwovens every morning. Perhaps you reach into the refrigerator for a drink from a water-filtering pitcher to start your day. (Water filters of all sizes, from pitchers to swimming pools, are nonwovens.)

If you clean up a spill in the kitchen with a Swiffer, you’re using one of the most recognizable nonwoven consumer products, now approaching “a billion-dollar brand,” Pourdeyhimi notes.

But nonwovens don’t always look like filters, wipes, diapers or cleaning pads. The synthetic leather you touch as you lace up your sports shoes is also an engineered fabric.

When you climb into your car, you’re surrounded by nonwovens, which make up dozens of vehicle components, including headliners, carpet backing, and custom-shaped leather- and plastic-like materials. And you may drive to work on an asphalt highway that has a nonwovens layer beneath it to help prevent cracking.

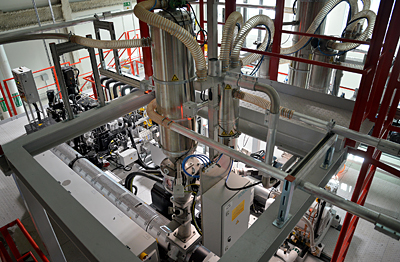

NC State’s new, one-of-a-kind manufacturing facility is a veritable United Nations of nonwovens: spunbond machinery from a Germany, a thermal calender from Austria, a hydroentangling system from France and a winder from Italy, boosted by bicomponent fiber technology from West Melbourne, Florida.

Nonwovens technologies have come together in innovative ways in North Carolina, providing a wealth of bragging rights. In fact, about 40 percent of the U.S. nonwovens industry is based in the Old North State, Pourdeyhimi says.

NC State has nurtured that nonwovens growth through research and industry partnerships for more than 25 years. It all began with the opening of a test facility on campus back in 1991, with seed funding from the National Science Foundation, the State of North Carolina and industry.

“With NSF funding, typically you shut down after eight to 10 years of government funding. We didn’t,” Pourdeyhimi says. The expansion hasn’t stopped since.

NC State’s Nonwovens Institute is home to the world’s first and only accredited academic program for interdisciplinary study of engineered fabrics. Faculty from the colleges of Textiles, Engineering and Natural Resources, along with colleagues from other universities, provide expertise in chemistry, mechanical and industrial engineering, bioengineering, chemical engineering, paper science and engineering, and fiber and polymer science.

The institute supported the work of 50 Ph.D. students last year across many programs at NC State as well as partner institutions both in the U.S. and United Kingdom. During their time on campus, all nonwovens graduate students rub shoulders with both academic and industry leaders and become familiar with advanced manufacturing facilities found nowhere else in the nation. That experience provides a “compelling advantage” over other candidates during job interviews, Pourdeyhimi says, recalling students recently hired with Kimberly Clark, 3M, Freudenberg and others.

Those companies are among the 68 industry partners in the Nonwovens Institute. More than 170 NC State alumni currently work in the nonwovens industry.

Both new companies and new technologies have gotten their start at NC State, thanks to the Think and Do approach at the Nonwovens Institute.

Research and development here has generated 80 U.S. and international patents. “We create not only jobs, but new industries,” Pourdeyhimi says. “We make things that haven’t existed – new applications.”

The institute also serves as a business incubator, an economic development engine that helps bring new products to market.

Below, you can get a glimpse of what’s under those new 65-foot ceilings on Centennial Campus.

This post was originally published in NC State News.

- Categories: