Creating Fibers – and Greener Jobs

By Jessica Roulhac

Assistant Professor Ericka Ford, a faculty member in Textile Engineering, Chemistry and Science (TECS) at the Wilson College of Textiles, wants the next generation to know about solution spinning. The tried-and-true spinning method is one of the oldest and is used to create synthetic fibers like Kevlar and spandex. With new ways to produce sustainable, high-performance fibers using chemistry in the lab, Ford is focused on producing fibers — and economic impact.

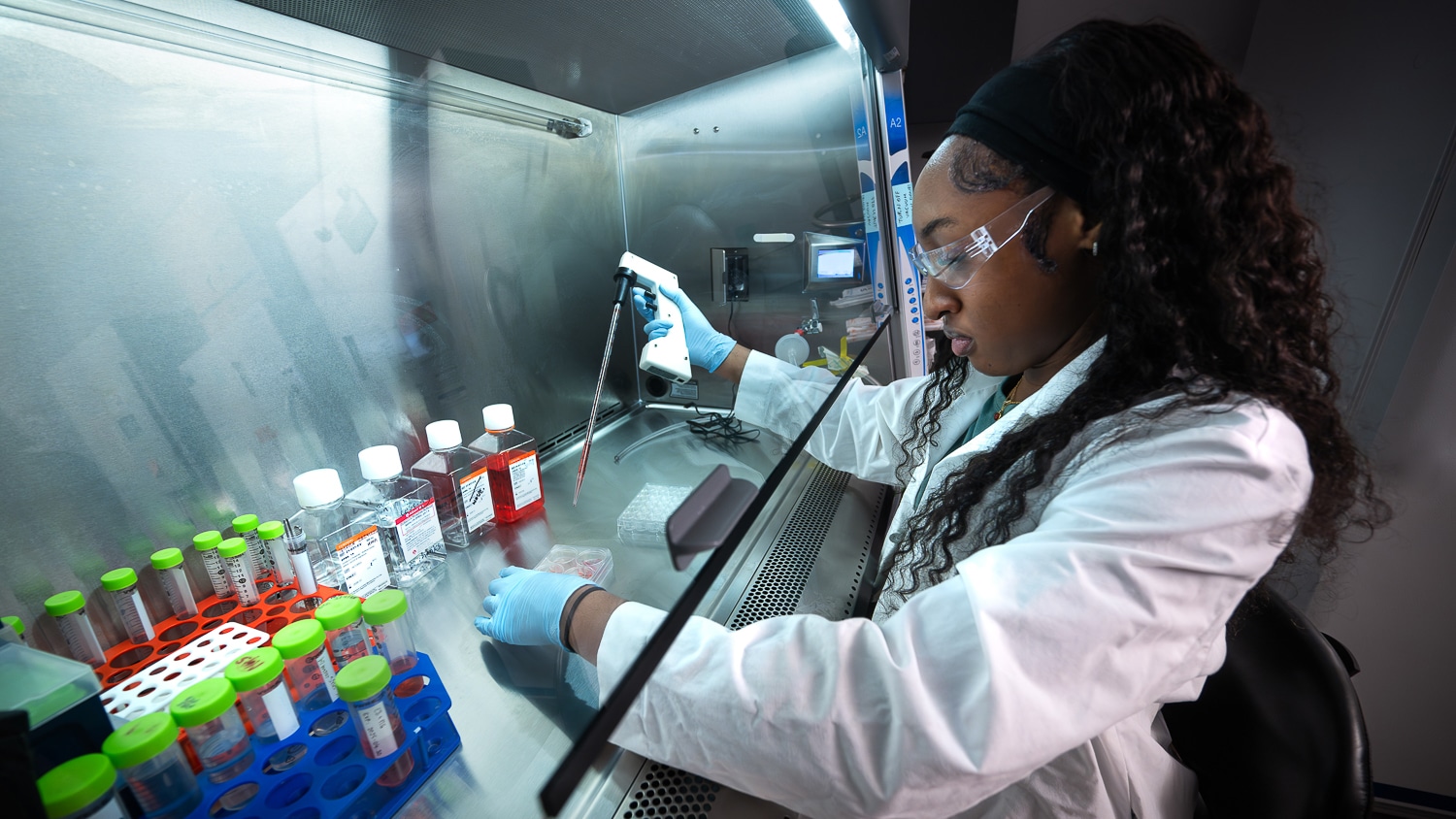

The work starts with the next generation of solution spinning professionals. With her own journey of mentorship, Ford wants to pay it forward. She believes that empowered students make confident decisions that can change the world.

“I tell my students that I’m training them to take my place,” said Ford, who also holds an appointment with The Nonwovens Institute at NC State. “I want them to be able to go out and represent my team, our college and our university.”

Graduate students like Javier Jimenez are in her lab. As part of Ford’s class requirements, he’s mentoring Isabelle Salzmann, a sophomore textile engineering student. Jimenez is pursuing his doctorate in fiber and polymer science. The mentor-mentee relationship models the importance of empowering students.

“Javier is very knowledgeable on the topic and always teaches me so much about polymer chemistry and about fiber science,” Salzmann said. “It’s been honestly one of the most rewarding experiences in my time in college.”

Research first

Ford’s journey to the textiles industry began in high school. She saw it as a stable career that introduced her to a niche community of passionate researchers. When it was time to go to college, she chose the Georgia Institute of Technology and earned her bachelor’s degree in polymer fiber engineering. She would later return to Georgia Tech to earn her doctorate in polymer, textiles and fiber engineering.

While pursuing her undergraduate degree, Ford was always curious about why things were happening. The curiosity prompted her to continue her education at The University of Southern Mississippi, where she earned her master’s degree in polymer science and gained the opportunity to work in Professor Emeritus Shelby Thames’ lab. Thames is a nationally recognized expert in polymers.

While the lab had an entrepreneurial spirit, Ford most appreciated how the concepts were grounded in science. In her lab today, she reminds her students that understanding the science is foundational for communicating findings to industry partners.

“Even with that entrepreneurial spirit, I still hold the students and myself to the standard that we must be good researchers and understand why it’s working,” Ford said. “We must be able to convey that simply and truthfully to our clients.”

What’s one of the best ways to put these skills to the test? Mentorship. While Jimenez is preparing his dissertation work, Salzmann is receiving one-on-one mentorship, which includes spinning fibers. She’s also learning from someone ready to enter the field.

Jimenez is learning, too.

“The best way to learn something is to teach it,” he said. “Isabelle has definitely stumped me. I’ve had to step back and ask, ‘Why does this happen?’ or ‘How do I explain this?’”

Sustaining solution spinning

When one thinks of fabrics, they are either natural or synthetic. Natural fibers, like silk and cotton, come from plants or animals. Synthetic fibers are produced in the lab through a chemical process. They are more easily mass-produced, more affordable for consumers, and can be designed as stain-resistant or even waterproof.

To create synthetic fibers, manufacturers use a process known as fiber spinning. There are two categories: solution spinning and melt spinning. Before a polymer can become a synthetic fiber, it has to be converted to a liquid. Researchers can either dissolve the polymer in a solvent through solution spinning — or melt it by way of the melt spinning process.

Solution spinning is used for materials that cannot handle heat. Researchers can also use natural polymers to create sustainable, high-performance fabrics. As consumers demand greener fabrics, manufacturers are listening. Increasingly, the industry requires skilled scientists, chemists and engineers — and Ford wants to prepare her students to not only fill the jobs but also create them.

There’s no better place to accomplish this mission than in the Wilson College of Textiles at NC State.

“When I think about communities and how much a plant can mean to that community, I feel like the research I’m doing, working with industry, is a way of giving back,” Ford said. “That’s a way of supporting an industry that can really change lives.”

Excellence in extension

Ford’s innovative research for solution spinning has positioned her as an expert in the field. Most recently, she was announced as part of the university’s inaugural class of Goodnight Early Career Innovators. This class of early-career standouts will receive $22,000 for each of the next three years to support their scholarship and research endeavors.

In 2020, Ford received the Outstanding Extension Award from NC State. At the time, she had 10 intellectual property disclosures and was on two published patent applications. Her patented technology has garnered the attention of industry partners from diverse sectors.

Nominated by TECS Department Head and Professor Jeff Joines, Ford is most celebrated for how her licensed technology is quickly and seamlessly put into practice by partnering companies. Industry partners see the value of solution-spinning and go to Ford and her team for guidance and leadership.

“While several faculty receive patents, Dr. Ford is unique in that companies have already licensed her technology (i.e., 5 license agreements) demonstrating her ability to translate her fundamental research into practice,” said Joines.

Ford has received more than $1.6 million in research funding for her lab from government sources, companies and research consortiums, including The Nonwovens Institute at NC State.

Receiving recognition as an accomplished solution spinner, she is in a unique position to provide the training and talent needed to sustain and create solution spinning jobs.

Through the Ford Innovation Team, she partners with industry to help companies, especially start-up companies, incorporate new fibers into textile markets that can only be produced through solution spinning.

The collaboration is rewarding and offers another way to generate economic impact. The team has four main areas in which they provide research and educational leadership to industry partners: solution spinning technologies in lignin fiber spinning, green additives for strengthening solution spun fibers, nanotechnology for clean water and environmental remediation, and formaldehyde-free finishes for cotton wrinkle resistance.

Ford is on a mission to be recognized as a world-renowned scholar in the advanced manufacturing of solution-spun fibers. Her goal is to see the art of solution spinning remain in the United States.

To empower the next generation, she’s teaching her students the value of mentorship. Those times in the classroom allow students to see first-hand that careful, thoughtful research delivers real-world results that industry partners can trust. The mentor-mentee relationships are a fresh reminder of the niche environment that attracts students and faculty to the Wilson College of Textiles.

There’s more work to be done, and Ford is up for the challenge.

“My goal is to educate the next generation so that they would understand this art,” Ford said. “This art should not be forgotten.”

- Categories: