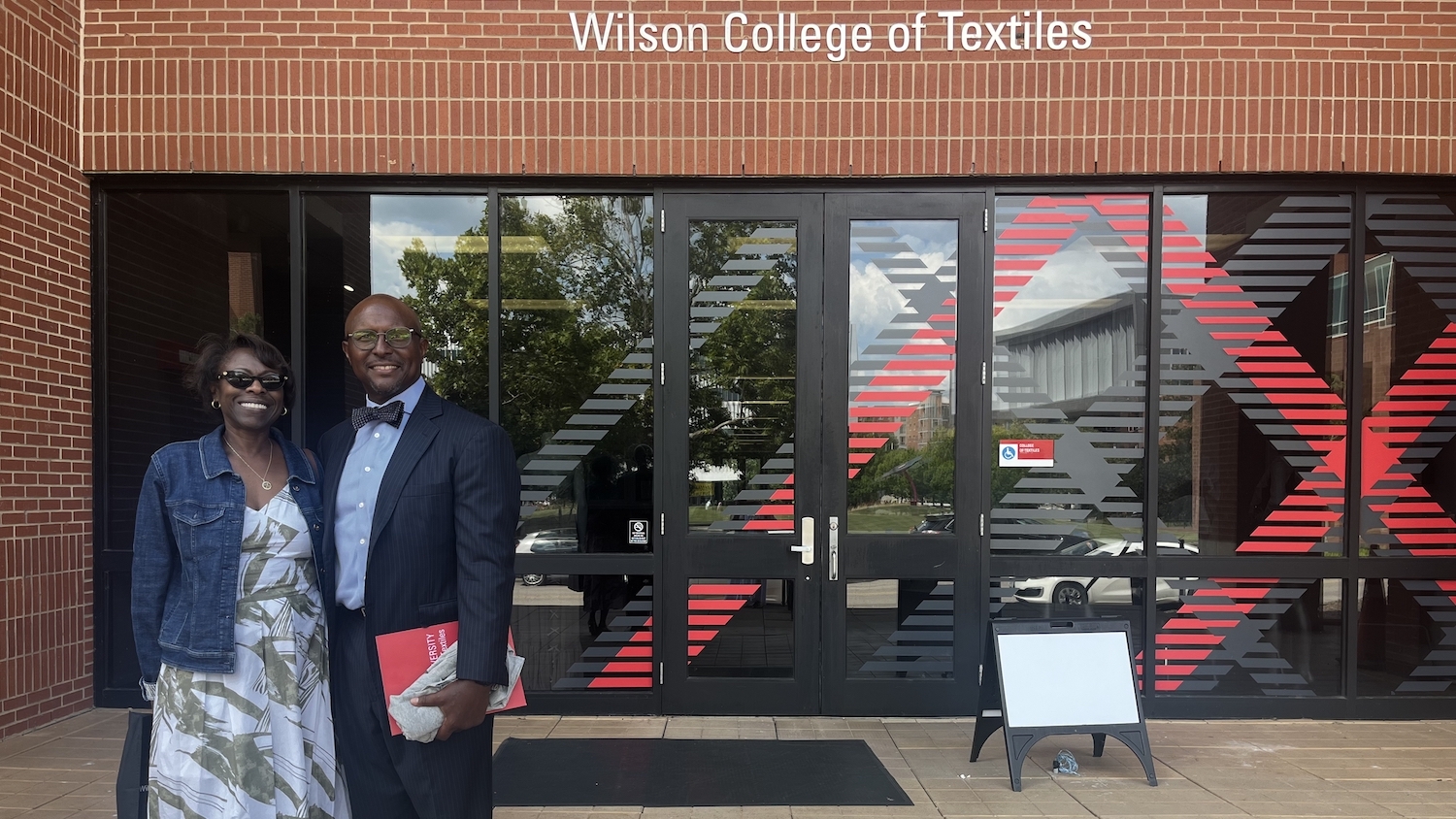

Cheryl Coley Makes Her Mark

For NC State double alumna and Wilson College of Textiles graduate Cheryl Coley, an internship not only filled a spot on her resume, but also led to a full-time position with a company she admires. After her graduation in 2016 (M.A. Integrated Manufacturing Systems Engineering), she went to work as a quality engineer for Technimark, an Asheboro, N.C.-based injection-molding company that designs and manufactures product for the consumer packaging, healthcare and industrial markets. It was a sort of homecoming, as she held three manufacturing and quality internships with the company between May 2011 and February 2015.

While earning her 2014 bachelor’s degree in Textile Engineering, she was a member of the textiles leadership fraternity Kappa Tau Beta, textile honors fraternity Sigma Tau Sigma, Tompkins Textile Student Council, the Textile Engineering Society and the NC State marching band, where she was a rank leader and a section leader. During her graduate education, she created a functioning pinball machine for an automation engineering course.

Through a built-in co-op program, Coley also worked at the John Deere Turf Care factory in Fuquay-Varina while she earned her master’s degree. She credits that experience with helping her make a living while she learned real life skills that she uses in her current position.

“As an intern, I loved being on the floor with the people and learning from them. They work with these machines day in and day out and ultimately are what drives the company.”

What are your current job responsibilities?

For the product segments that I am responsible for, I ensure that the quality of the parts are acceptable per our customer standards before they leave the door. Some days I am primarily working at my desk doing data analysis and others I am spending most of my time on the floor with operators. I enjoy my days where I have a good balance of both.

What brought you back to work at Technimark, where you interned?

As an intern, I loved being on the floor with the people and learning from them. They work with these machines day in and day out and ultimately are what drives the company. I worked with tons of people and the friendly atmosphere is what drove me to seek full time employment…As a quality engineer, it’s nice to see several things I worked on as an intern still in place and utilized at the company. Now being full time, I’m enjoying trying to teach the interns we have there for the summer. I know what it’s like to be in their shoes.

What is the biggest difference between being in college and working in industry?

No homework!

What experiences did you take from COT that you can say have helped in your new career?

Lean Six Sigma class and working on so many projects in groups. In a manufacturing plant, it is imperative to work well on a team in order to produce good products.

Was there a professor at COT that made an impact on you? Who was it and why?

Dr. Jeff Joines, Textile Engineering, Chemistry and Science department head. He was a huge help throughout my undergraduate and graduate career. He is the one who encouraged me to pursue my master’s degree.

What is the best thing about the city you now live in?

Being close to my family! But we also have the North Carolina Zoo.

What did you do in your spare time while attending NC State?

I was in the marching band and pep band during my time as an undergrad. I loved every minute of it. The band actually traveled to Spain and performed in a parade, which was a once in a lifetime opportunity!

Do you have any advice about job searching?

Don’t feel like you have to take the first job offer. Get as much interview experience as you can — it makes a world of difference when trying to find a full time job.

- Categories: