Ph.D. Student Sophie Nunno-Gorbachev Researches Direct-to-Textile 3D Printing at The Nonwovens Institute

Sophie Nunno-Gorbachev

Degree Type: Ph.D.

Expected Graduation Year: 2023

Department/School: Wilson College of Textiles

Program: Textile Technology Management

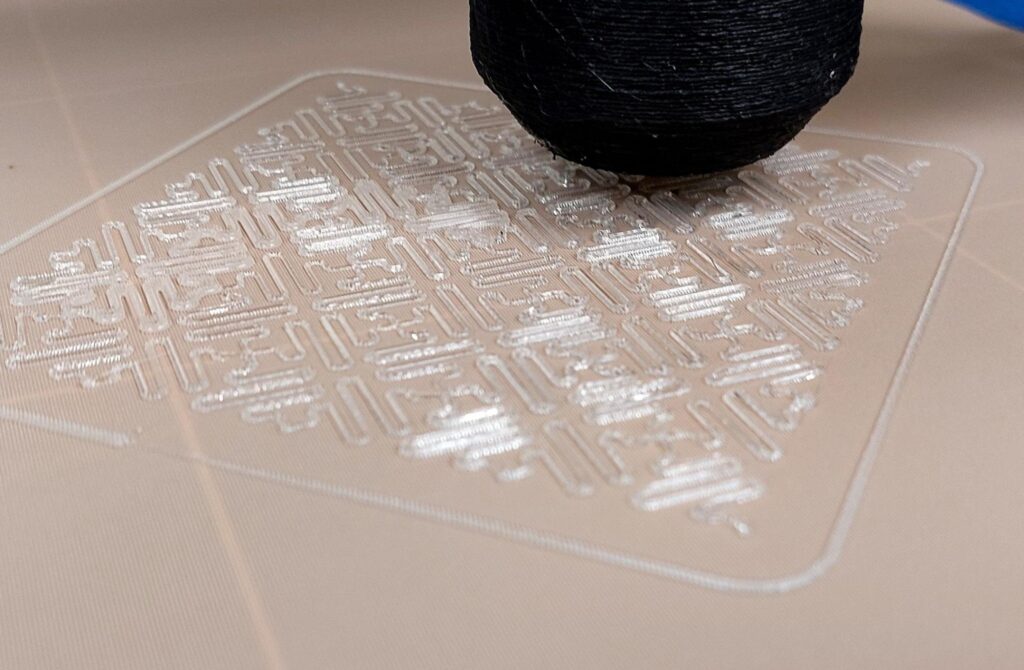

Research Project: Direct-to-Textile 3D Printing

Professor/Faculty Advisor: Dr. Behnam Pourdeyhimi, NWI/NC State University

How did you come to have an interest in nonwovens?

I had the opportunity to attend NC State University and study textiles for my undergraduate degree, during which I was introduced to nonwovens as “highly engineered textiles.” Through my graduate studies, I saw how the nonwovens industry channels all aspects of textile production from polymer to fiber to fabric to solve some of the greatest challenges on our planet. I have worked on nonwoven projects for applications in filtration, medical textiles and apparel, and these experiences showed me how the nonwoven industry solves complex problems through polymer science, textile engineering and new product development.

Why are your research/findings particularly important/compelling for nonwovens applications?

The objective of my NWI research project is to develop a better understanding surrounding direct-to-textile 3D printing, to investigate 3D-printed structures and prototypes, and to study the interaction between 3D-printed parts and fabric.

Current pre-production and manufacturing processes present limitations, such as complications with materials management, significant fabric waste and slower-than-ideal manufacturing times. The implementation of additive manufacturing may allow for design specifications to be printed directly onto a fabric, reducing material waste, simplifying the sourcing process and streamlining manufacturing.

Where do you see yourself upon completion of your studies?

During my time with NWI, I was able to see industry and academia cooperate to solve mission-critical problems through the creation of innovative science-driven, and market-ready technology. I want to bring this collaborative mindset and workflow to the adjacent textile and apparel industry with my recent textile-industry start-up, Fibonix, through the precise use of science-based tools, inventive design, and crystal-clear analytics.

When you are not studying and doing your nonwovens research project, what are your personal interests, hobbies … any activities you would like to highlight?

In my free time, I enjoy sewing, painting, rock climbing, playing chess, running and cooking, as well as statistics and film photography.

This story was originally published by The Nonwovens Institute.

- Categories: