Graduate Research Spotlight: Faisal Abedin (Ph.D. FPS) Finds New Ways to Evaluate Activewear Materials

By Sarah Stone

By the time Faisal Abedin graduates with his Ph.D. in Fiber and Polymer Science, the doctoral candidate will have developed a new way for activewear brands to measure the effectiveness of their apparel. Since 2020, he’s served as the only research assistant for the project led by Professor Emiel DenHartog and sponsored by The Woolmark Company and Australian Wool Innovation.

This research experience has been the perfect fit for Abedin, who aims to land a job at an activewear giant like Adidas, Under Armour or Nike post-graduation.

Below, he explains more about the testing he’s developing for activewear textiles.

Tell us more about your research. What do you hope to accomplish?

We are working on a new dimension of testing for activewear industries to assess moisture management in changing conditions using four different fiber types: wool, cotton, viscose and polyester.

Our research analyzes the comfort of the post-exercise period. In more general terms, after sweating from an activity/moderate exercise, when our body starts drying, we feel a chill as our body temperature drops. This feeling can sometimes be severe; for example, if rock climbers reach the clifftop after a long hike and rest for a while, their mean body temperature will drop very quickly because of the windy clifftop conditions. Our goal with this research is to establish test procedures and protocols of activewear for that kind of situation.

Our research also focuses on differentiating comfort aspects for hygroscopic natural fibers and non-hygroscopic synthetic fiber types; hygroscopic fibers are ones that absorb moisture naturally from the environment. To conduct this research, we are using standard test methods and our own developed protocols and test setup.

How will this research fill either a gap in knowledge or an industry need?

The sportswear industry relies mostly on measurements that don’t take into account the changes that happen when we exercise outdoors. However, our research entirely focused on evaluating sportswear performance in a dynamic condition, which means considering environmental factors such as temperature, humidity and wind, as well as physiological factors such as skin-microclimate temperature and humidity.

The most impactful aspect of our research is that we are validating our test protocols and procedures through fabric-level lab testing, garment-level manikin testing and human trials. This combination of testing methods helps us fully understand the material’s behavior both in a lab setup and under realistic environmental conditions. Interestingly, the textile industry is funding the project, so, undoubtedly, this research has an immense significance and impact on the activewear industry.

For my research, I used a handful of testing instruments to measure the physical properties and performance of the textile materials in fabric and garment form.

What sort of testing have you been conducting to develop your research?

For my research, we try to simulate environments. To measure the physical properties of fabrics – for example, air permeability, strength and weight – I used basic testing instruments, which are pretty standard in the textile industry.

However, for the performance testing instruments, I used advanced testing facilities provided by TPACC [Textile Protection and Comfort Center]. I used the Kawabata Evaluation System – which mimics human touch –, moisture management testing instruments, sweating guarded hot plates, dynamic hot plates, and the thermal and sweating manikins.

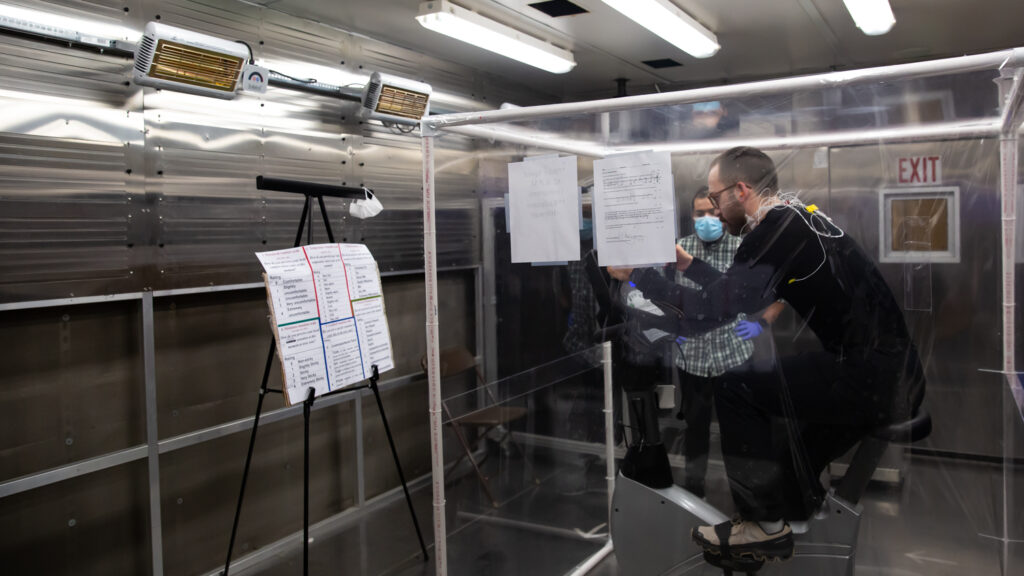

To me, the most exciting part was the physical wear trials I conducted in a controlled climatic chamber in April of this year. It allowed me to train myself with Institutional Research Board procedures and, most importantly, helped me better understand skin-clothing interactions and evaluate results I found in lab testing.

How do you think this experience has helped you grow as a scientist?

As the only research assistant on this project, I have to do everything. I have to manage my testing. I have to manage raw materials, plan test setups and their protocol, analyze data after testing, and write reports. I always discuss everything in detail with my advisor about the testing plan’s feasibility and results. We have different milestones in different months for the project, so I have to plan and organize to ensure we hit those milestones.

Working on the project helped me develop as an individual researcher and prepare for a managerial position. I took some advanced courses about polymer science, nonwovens and textile composites, which helped me think deeply about textile materials and their structure and properties. Courses outside of my department, such as statistics and mathematical modeling, have made me more aware of the application of my research. My bachelor’s and master’s were in textile engineering, which was more focused on manufacturing aspects of textiles. But here at NC State, the FPS program has helped me learn more about textile materials, properties and mechanics.

What’s next?

The research project ended on June 30, and most of the project’s milestones were met. The next step for me is to submit research articles to peer-reviewed journals for scientific publication, so, I’m putting most of my attention into writing right now. I plan to defend my dissertation in the fall of 2022.

- Categories: